产品服务

Radiant G system is designed for use on hilly or sloping ground like golf courses and other complex terrain. Our new TerrainRac G system is cleverly designed to allow for vertical north south adjustment as well as horizontal east-west adjustment. The G System has international patents pending protecting the ingenuity of our intellectual property owned by Radiant. Trying to make your tables look level is now simple with TerrainRac G. Your installation time will be significantly reduced using TerrainRac G.

High Space Utilization

With Radiant TerrainRac G, it is possible to utilize more space within a site perimeter. Maximize your use of land resources with the G factor.

Significant Savings

1.G design is engineered for strength and durability and minimizes material use without compromise to strength and load.

2.A high percentage of factory pre-assembled components means faster installation, hence lower installation costs.

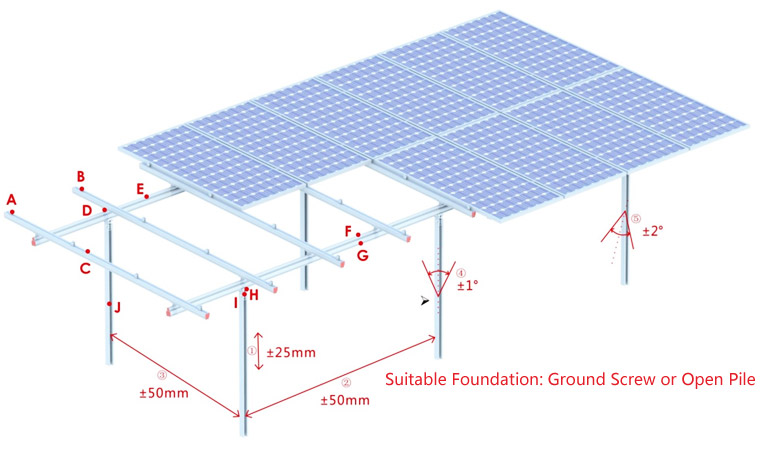

3.Hilly terrain can be challenging to installers. When installing ground screws or piles errors often occur when levelling on hills. G system is a very forgiving system when a machine operator lapses concentration.

4.G system is a Modular system and makes the installation process easier.

High Efficiency

G system attaches to either ground screws or open piles (either method is supplied by Radiant). Either attachment is highly efficient coMPared to expensive concrete foundations. In fact our system is up to 10 times more efficient than using concrete.V

Flexibility Like No Other System

CoMPared with the traditional racking systems, G system has the most generous vertical adjustment, and our patented rail profile and RB Adaptor kit allows for generous east-west rail adjustability. Additionally, the G system cross beam can be used for cable management to hide unsightly cables.

Expansibility and CoMPatibility

G system can be applied to both landscape or portrait module installation. Double glazing modules also be coMPatible.

Mechanical Testing and Verification

Radiant TerrainRac G system is designed to your specific project needs. All components have been reliably tested and have undergone independent static analysis to ensure your project will with stand the harshest climatic conditions

Maximμm Service Life

Cross Beams, Base Rails, Cross Beam Splices and clamps are made from Alμminμm (AL6005-T5) and Stainless Steel (SUS304)